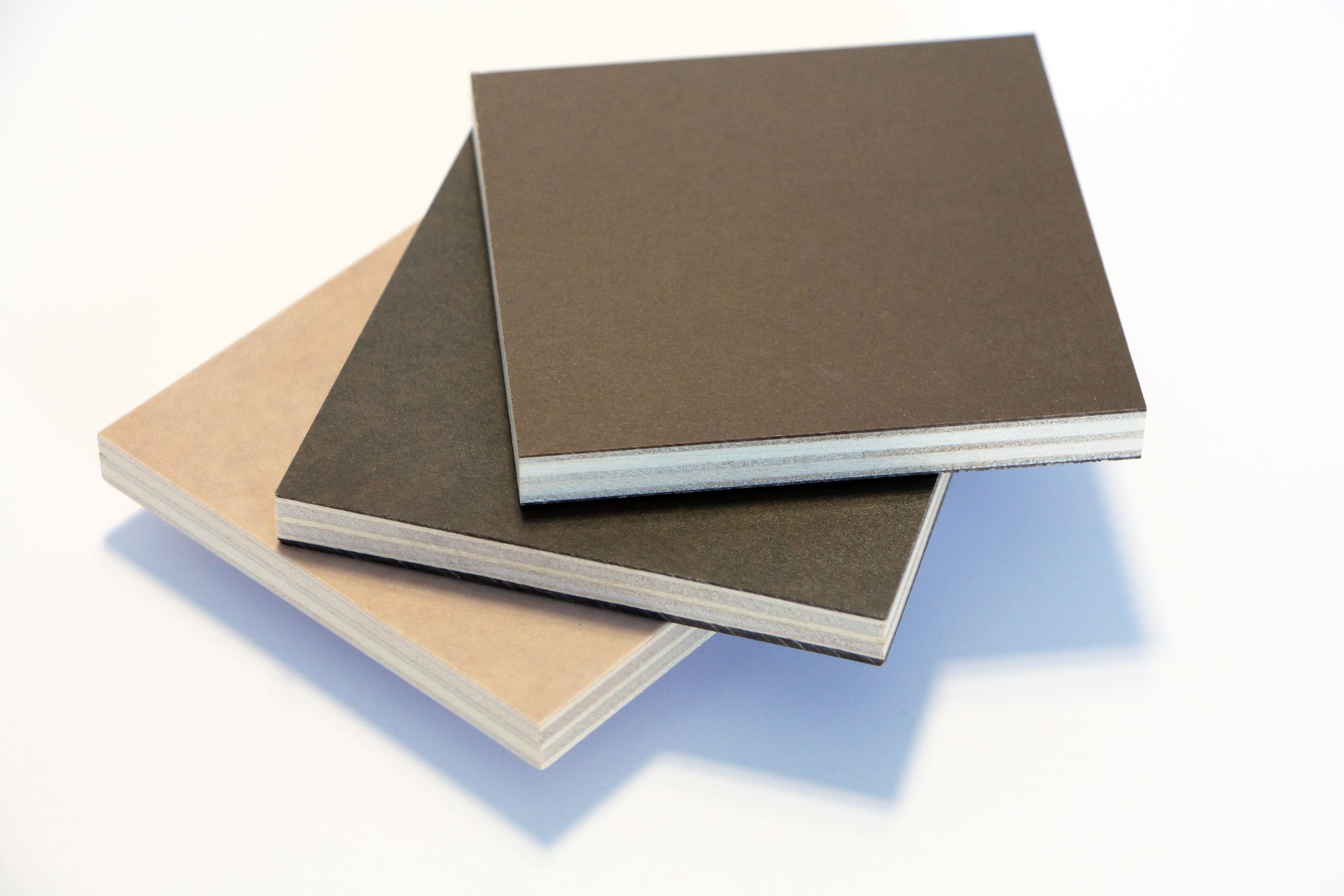

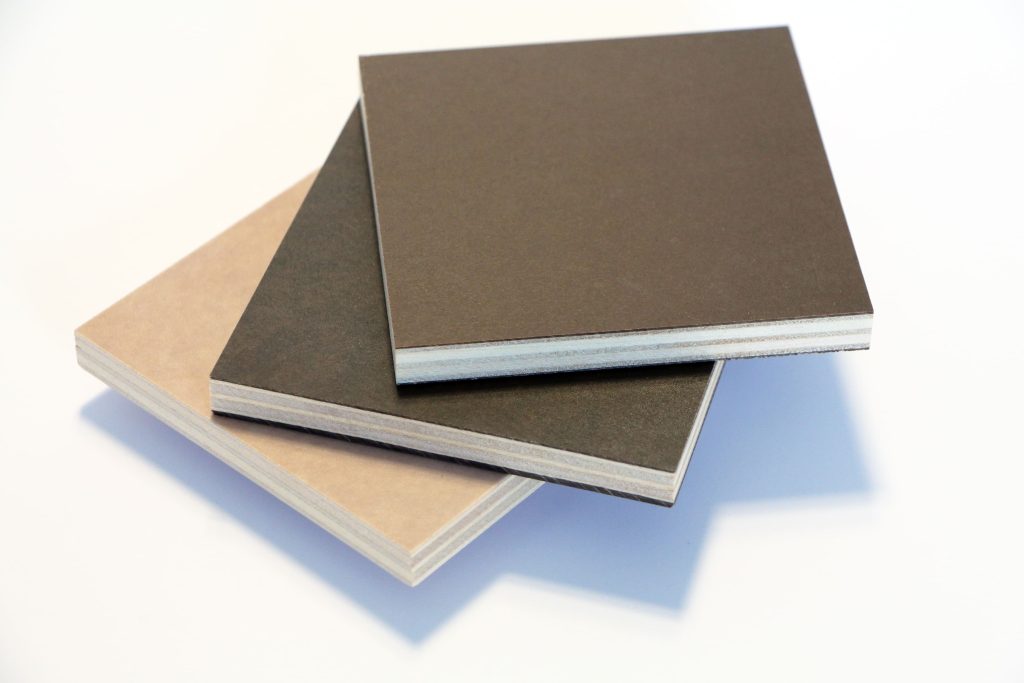

Thermoplastic composite sheet

Architectural interior wall panel from recycled wood and biopolymers

Innovation details

Benefits / Impacts

1) Application for architectural interior wall panel system and interior furniture,

2) Non-fire-retarded version consists of almost 100% bio-based materials,

3) Fire resistance: material classified as V-0 at 4 mm thickness (UL94),

4) Possibility to use wood waste (urea-formaldehyde bonded particle board),

5) Easy to recycle,

6) Cost efficient,

7) Customisable exterior finish.

Images

Thermoplastic composite sheet Process

Thermoplastic composite sheet Process

Technical Features

Next steps, R&D needs

Increase biobased parts,

Production process optimisation,

Product full characterization

862942