INACELL

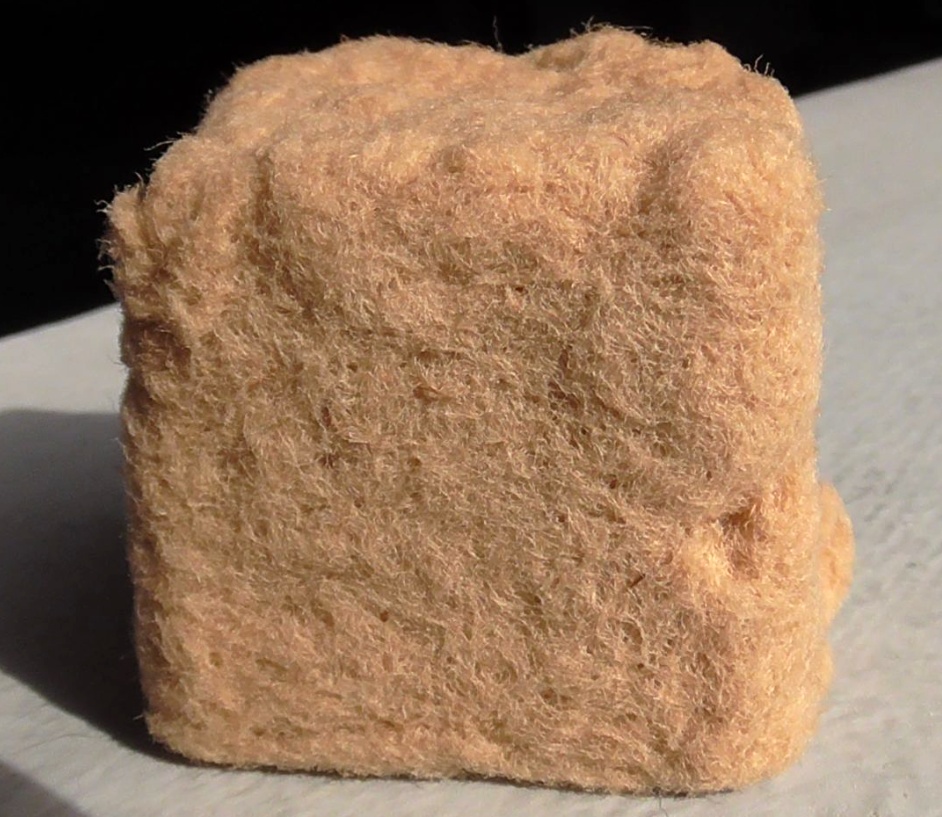

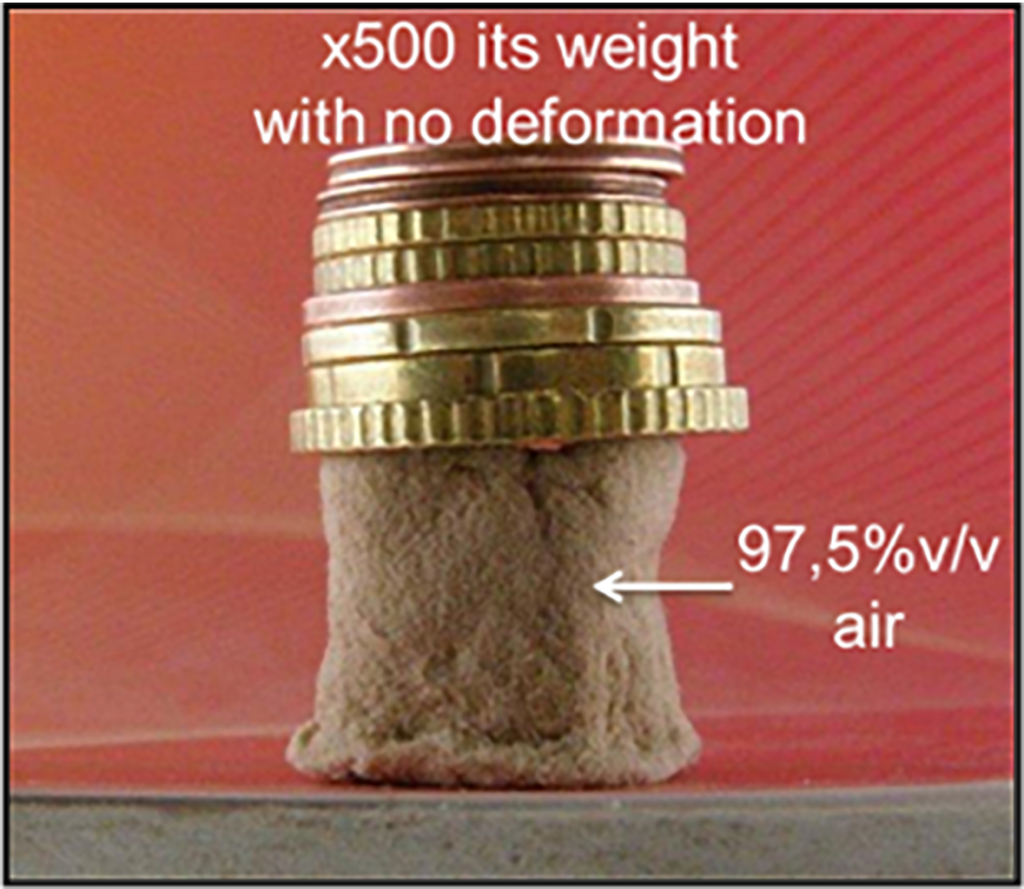

Manufacture of wood-fiber resin-free thermal insulation boards

Innovation details

Benefits / Impacts

The innovation is sustainable and environmentally friendly: By utilizing wood fibers, a renewable and biodegradable resource, the product promotes sustainability and reduces dependence on non-renewable materials. It also reduces the environmental impact associated with traditional insulation materials.

The innovation improves indoor air quality: Resin-free insulation boards minimize the release of volatile organic compounds (VOCs) that can affect indoor air quality. This is particularly beneficial for buildings where maintaining a healthy indoor environment is crucial.

The innovation contributes to moisture regulation: Wood fibers have natural hygroscopic properties, allowing them to absorb and release moisture. This helps to regulate humidity levels within the building, preventing moisture buildup and potential issues such as mold growth and deterioration of building materials.

Images

Next steps, R&D needs

The innovation is in TRL4 and needs further progress to TRL6 that will include an industrial process.

Partners

Currently an Engineering company that will design the industrial plant.